The first thing that clicks our mind after reading the title is: What is a slurry pump? So, starting with this part, a slurry pump is a kind of pump that is exclusively used for pumping liquid that has solid particles mixed in it. There are different kinds of slurries, so you can find various types of slurry pumps (such as industrial slurry pump) used for pumping multiple types of slurry.

What are the types of slurry pumps?

The four main types of a slurry pump include:

- Horizontal slurry pump

- Vertical slurry pump

- Submerged slurry pump

- Submersible slurry pump

What are the factors that decide the right type of slurry pump?

Many factors decide which slurry pump you should buy. Some of these factors include:

- The concentration of the solid particles

- The size of the solid materials

- The shape of the solid objects

- The composition of the solution

How to choose the best slurry pump?

As we know, many brands are selling their slurry pumps and claiming that they have the best ones. But we don’t have to get in their trap. Rather we have to think wisely and then decide which pump should we buy. Below we are mentioning some factors that you must keep in mind for buying the best slurry pumps.

- The impeller

Make sure to choose a pump that has the impeller made out of elastomer. You can also opt for the pumps having chrome impellers. Also, another thing that you should take care of is that the impeller must have vanes. It is because these vanes help in making centrifugal force to the liquid.

- The casing

Next comes the casing of the slurry pump. For this, make sure that the casing is semi-volute. You can also go with the concentric casing. Also, be careful to choose a casing that can withstand high operation pressure capabilities.

- The shaft

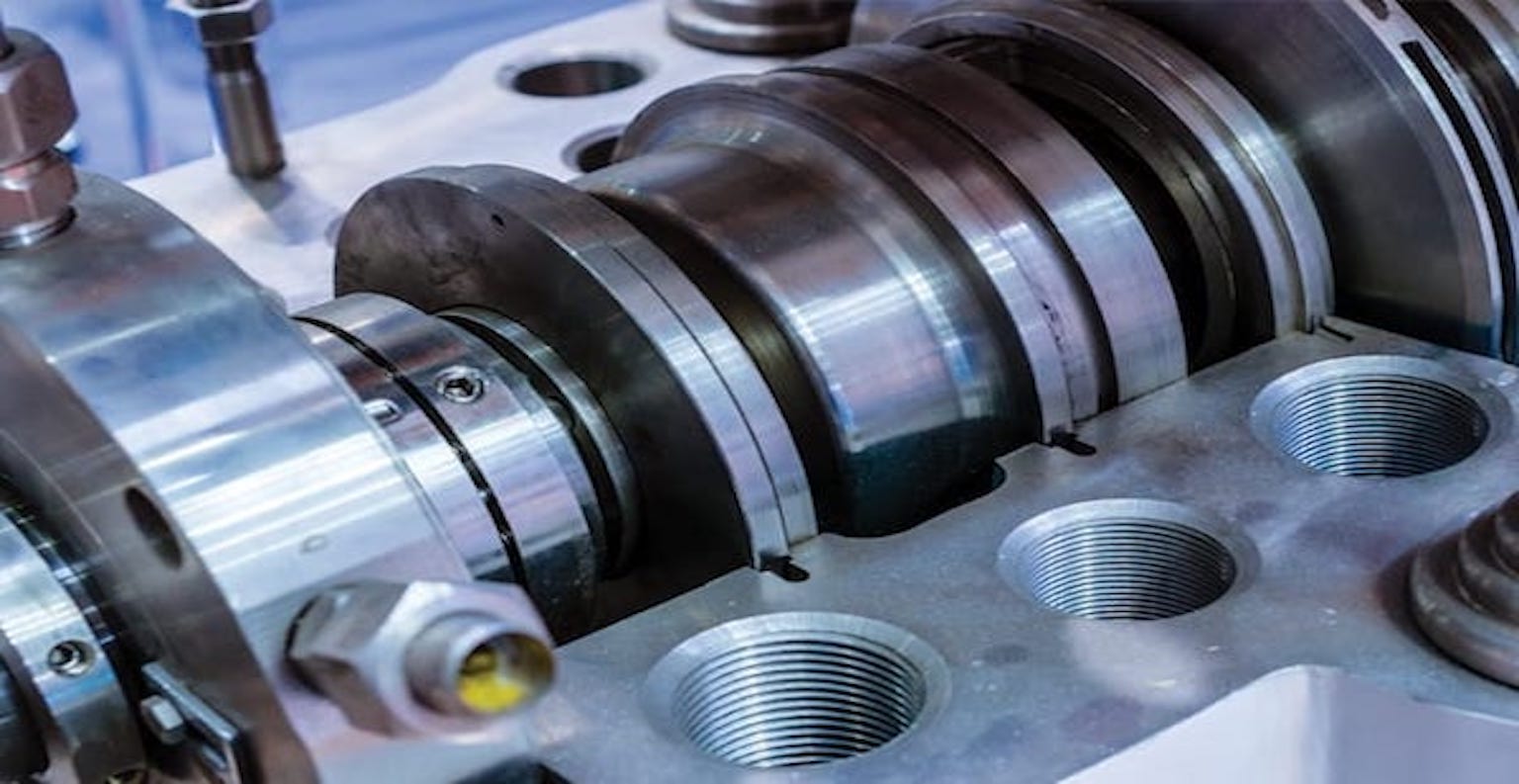

A good slurry pump is the one that has a large diameter shaft featured with a short overhang installed in it. This construction will help in reducing the deflection. Also, it will aid in minimizing vibrations.

- The shaft sleeve

Make sure to choose a hardened sleeve which has anti-corrosion properties. Moreover, it must have O-rings that protect the shaft.

- Shaft seal

The last thing that you have to take care of while choosing the best slurry pump is the shaft seal. Opt for a mechanical seal. As an alternative, you can also choose a packing seal or even an expeller seal.

Advantages of Industrial Slurry Pumps

- Strong machinery

- Low investment

- Stainless steel material which long lasts

- Easy maintenance

- Simple usage

Applications of Slurry Pumps

Slurry pumps are preferably used for many applications. These include pumping water for domestic needs, hot water circulation, boosting pressure, supplying water to different areas, regulating boiler water assistance in fire protection systems, and sewage draining. Industrial Slurry Pumps have a broad spectrum of purposes.

- Construction

Slurry pumps are widely used in various steps in construction, such as

- Pumps for wash water (sand and gravel)

Vertical pumps are the best for wash water purposes and are preferred over horizontal pumps. But horizontal pumps of appropriate length can also be used to meet your requirements.

- Pumps for sand transportation

Sand transportation is mostly done with slurry pumps. Horizontal pipes with rubber lining are an ideal choice for this purpose.

- Pumps for tunnel dewatering

The ideal choice for the starting transportation stage is the vertical pumps as the front pumps use the drainage pumps. If we consider tunnel dewatering, there are many factors such as distant horizontal pumping, cuttings from full-face boring, small tunnels, etc. The selection of a slurry pump depends.

- Waste and Recycling

Slurry pumps are used in the following ways in waste and recycling.

- Pumps for effluent handling

It would be best if you chose metal pumps to handle the discharge of waste and recycling materials. You can use either horizontal or vertical slurry pumps, according to your needs.

- Hydraulic transportation of light waste

Use horizontal slurry pumps with vortex-induced flow turbines while hydraulic transportation of light waste.

- Pumps for soil treatment

Slurry pumps work efficiently in soil treatment. They can bare extreme temperatures and rough climate because of their vigorous construction.

- Chemical

- Pumps for acid slurries

Use horizontal slurry pumps with stainless steel or rubber while dealing with acid slurries.

- Pumps for brines

Slurry pumps are the best option to deal with brines because brines can usually damage the pump due to their abrasiveness.

- Pumps for caustics

Caustics is a light and easy application so that you can use either rubber or metal slurry pump in this case.

Conclusion

A slurry pump is a great thing that provides us with many benefits. But before buying one, you must make sure that you are buying the right slurry pump that is perfect for the type of slurry that you want to pump out. Moreover, buy the pump from a trusted source and never compromise on the quality of the pump that you are buying.