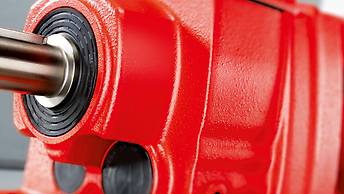

Our gear units can be used flexibly – be it for a specific customer solution or a standard application. Select your gear unit from a wide assortment. The right size, power, gear ratio, the right torque as well as design and surface. Tailored to your application requirements and to your area of application.

- Standard Gear Units

Five standard gear unit series to perform your drive tasks: one, two and three-stage helical gear units, series R: Output torque from 50 Nm – 18 000 Nm; two and three-stage parallel shaft helical gear units, series F: Output torque from 130 Nm – 18 000 Nm; two and three-stage helical-bevel gear units, series K: Output torque from 80 Nm – 50 000 Nm; two-stage helical-worm gear units, series S: Output torque from 92 Nm – 4,000 Nm; one and two-stage right-angle gear units, series W: Output torque from 25 Nm – 180 Nm. Other than a few exceptions, the standard gear units are also available as multi-stage gear units – just ask!

- Getriebe Fuer Mischer

The agitator design is ideal for use with mixers, agitators, surface aerators, and kneaders. It is thus a perfect fit for the biotechnology, pharmaceutical, chemical, food, beverage, recycling, environmental technology, paper, cellulose, and wastewater industries.

- Servo Gear Units

Our servo gear units stand for dynamics and precision. They feature a sturdy, warp-resistant design and a compact build. We offer low-backlash planetary servo and helical-bevel servo gear units that cover a torque range of 25 Nm to 3,000 Nm and can be used even in complex motion control applications.

- Stainless Steel Gear Units

Our stainless steel gear units are built for use in areas and applications that involve frequent cleaning. They are resistant to acid and alkaline, and equipped with many other hygienic features. Their IEC and NEMA adapters, also made from stainless steel, allow for flexible motor mounting. These stainless steel gear units are ideal for applications in both the food and beverage industry and other sectors.

- Explosion-proof Gear Units

You don’t have to sacrifice performance, torque or dynamics to work in potentially explosive atmospheres. At least, not if you’re using our explosion-proof gear units. We offer a broad range of ATEX-compliant solutions from our modular system.