PWR

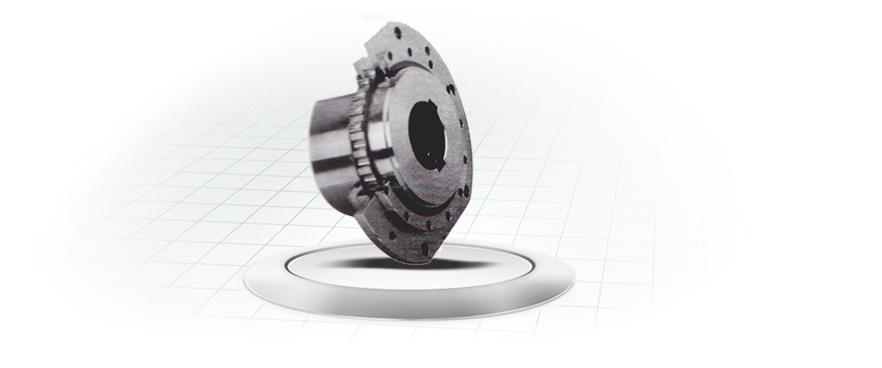

The PTC wire drum coupling is designed for installation in drum drive of crane and conveying system. The drum coupling can be used in the very difficult and rough operating conditions of iron and steel work and continuous heavy load operations in shore cranes.

1) With compact design and capable of transmitting large radial load, the PTC wire drum coupling enjoy longer life and minimum loss of power.

2) With construction of crowned rollers and bores which are formed of both half circular bores of hub and sleeve, angular misalignment can be allowed upto ±1。30、

3) According to size of couplings, maximum ±3㎜~±8㎜ of end float can be absorbed.(See dimension table) Drum couplings are not suitable for transmitting axial forces.

4) With design of decreasing slip movement of rollers by construction of minimum backlash between crowned rollers and cylindrical bores,the relative movement between rollers and bores, which is cause of wear, is considerably reduced due to the natural movement of drum.

5) In the transmission of power, a stamping hardness of the rollers profile is produced, with which higher wear resistence is achieved.

The PTC drum coupling absorb pressure stress which were caused by the torque and the radial load larger surfface. The danger of rollers and bore breakage due to bending stress is excluded through this design. A comparison of the bending stress with involute gear, the circular toothing produces low value of the stress dramatically.